The Smart Factory has to meet many different challenges: machines that autonomously coordinate production processes, service robots that cooperate smartly with humans on assembly lines and driverless vehicles that autonomously complete logistics orders.

At Weidmüller, we have been dealing with Industry 4.0 and digitalisation since the early days. As a pioneer of Industrial Connectivity, we are already offering specific solutions that enable manufacturing companies to use innovative analysis technology and web-based services – even with existing machines.

Here we'd like to give you an insight into the journey towards the Smart Factory as well as solutions in the areas of Industrial IoT, Machine Learning, Power Management, Modular Infrastructure Concepts and Single Pair Ethernet.

The Smart Factory is based on the Industrial Internet of Things, which enables the continuous exchange of data between all participants.

In addition to our digital trade fair experience, we would also like to invite you to dive deeper into individual topics and to get in touch with our experts. For this purpose, we have put together a comprehensive webinar offer for the next three months.

This is a YouTube video. By clicking on this video, you agree to Google/YouTube's Privacy Policy & Terms of Use . You also agree to our Privacy Policy.

The Industrial IoT enables continuous data exchange between all participants – from production robots through to warehousing and microchips. Acquire, understand and capitalise on data – and offer your customers precious added value.

With our innovative Industrial IoT solutions, we help industrial companies identify individual potential for Industrial IoT applications, develop needs-based solutions for the Smart Factory and successfully integrate them into existing structures.

With our intelligent sensors designed for industrial use, you can quickly and easily integrate your drive into the Industrial IoT. After all, millions of drives and electrical devices are not connected to the Industrial IoT.

From data acquisition and pre-processing through to data communication, our extensive portfolio ranges from the sensor to the cloud. Access valuable data and information in greenfield and brownfield applications.

With our total solution from a single source, implement individual, platform-independent services for your specific use case. Whether in the cloud or on-premise – we offer tailored solutions for the optimal implementation of business processes and services.

This is a YouTube video. By clicking on this video, you agree to Google/YouTube's Privacy Policy & Terms of Use . You also agree to our Privacy Policy.

With u-mation, Weidmüller offers a complete service for the automation and digitalisation of your machines and systems. Benefit from the perfect interaction between all components and optimal integration into your systems.

Lay the foundation for your Smart Factory: Get to know the most innovative I/O system on the market "u-remote" and register now.

The webinar is unfortunately already over. A recording will follow soon.

u-control web: one of the most compact control systems on the market meets flexible engineering software.

The webinar is unfortunately already over. A recording will follow soon.

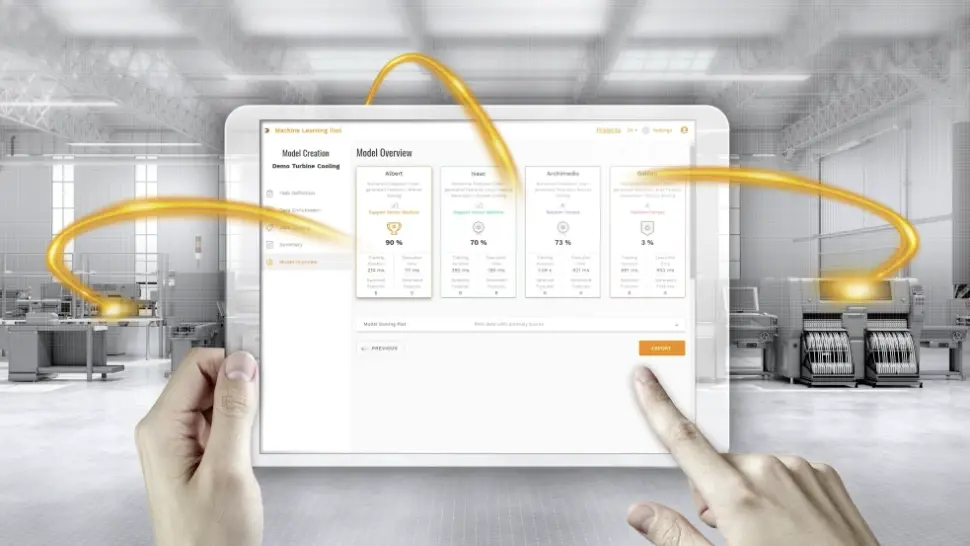

Besides the acquisition and distribution of signals and data, evaluating data is currently the main challenge in the Smart Factory. Companies need to utilise data to harness untapped potential, further increase efficiency and productivity of systems and create new business models. Weidmüller software plays a crucial role in this.

With our simple and highly intuitive Automated Machine Learning Tool, domain experts can, for example, independently generate a model for their use case in less than an hour, something which a data scientist would previously have needed several weeks or months to do as part of a project.

Or together with our data experts, develop an Industrial Analytics solution for your use case. We will help you design the ideal data infrastructure and select the most suitable sensors and components. Our analytics modules are tailored to your use cases in order to adapt the computing capacity and data transmission in line with your existing IT environments.

As the pioneer of Industrial Connectivity, we want to make machine learning widely available in industry.

This is a YouTube video. By clicking on this video, you agree to Google/YouTube's Privacy Policy & Terms of Use . You also agree to our Privacy Policy.

Learn more about the connection between data science and automated machine learning from our Data Scientist, Dr Daniel Kress.

Everyone's talking about digitalisation, but we want to use it to provide added value even at the end of the line. We want the solution developed by Weidmüller to help us take the next step

Easily create, operate and optimize ML models - Without expert knowledge in data science

This is a YouTube video. By clicking on this video, you agree to Google/YouTube's Privacy Policy & Terms of Use . You also agree to our Privacy Policy.

Make your machines smart and decide whether you want to develop solutions together with our data experts or harness the benefits of artificial intelligence independently using the Automated Machine Learning Tool.

This is a YouTube video. By clicking on this video, you agree to Google/YouTube's Privacy Policy & Terms of Use . You also agree to our Privacy Policy.

More and more factories are being transformed into more efficient and cost-sensitive production facilities. Due to the introduction of the Industrial IoT and the implementation of sensors as well as PLCs and control computers in the Smart Factory, there is a greater need for better power management systems.

In this connection, production processes constantly need to be made more efficient. Our PROtop power supplies and power management solutions combine excellent performance data with exemplary sustainability, which has a positive impact on the productivity of the entire production facility.

Maximum efficiency and high MTBF values ensure sustainable energy savings as well as

permanently high system availability. With integrated ORing MOSFETs, you can also reduce your system costs.

Thanks to the future-oriented DCL (dynamic current limiting) technology, high pulse reserves are available at all times. The resulting dynamic range can be used for the reliable triggering of circuit breakers or for powerful motor starts.

Communication-enabled components form the basis of networked production in order to fully leverage the potential of Industry 4.0. CANopen and IO-Link communication protocols enable complete data transparency through to the cloud, as well as remote control capability for integration into your machine controller.

Arrange an appointment: Discuss the most appropriate solutions for your situation directly with our experts.

This is a YouTube video. By clicking on this video, you agree to Google/YouTube's Privacy Policy & Terms of Use . You also agree to our Privacy Policy.

In the Smart Factory of the future, the only fixed elements are the external walls. Machinery and equipment, on the other hand, can move freely and communicate with each other in the Industrial IoT. A decentralised supply and data infrastructure is a key requirement here. With the Smart Grid solution, you can cost-effectively implement decentralised power management.

The modular Carry Over Parts principle offers a wide range of combination options and makes it possible to transition from IP20 to IP65 cost-effectively.

Network your automation and digitalisation in the field with decentralised remote I/O systems that let you expand functionality as and when you need it.

Take advantage of a comprehensive, ever-expanding product range that meets all relevant safety standards.

Learn more about our FieldPower® modular system and how you can use it for decentralised automation or download our free-of-charge whitepaper.

This is a YouTube video. By clicking on this video, you agree to Google/YouTube's Privacy Policy & Terms of Use . You also agree to our Privacy Policy.

We are getting the factory ground ready for the factory of the future: by bringing Bosch Rexroth's Smart Floor to life. In the factory of the future, the only fixed elements are the external walls. Machinery and equipment, on the other hand, can move freely and communicate with each other in the Industrial IoT. A decentralised supply and data infrastructure is a key requirement here. With the Smart Floor, Bosch Rexroth has developed a system in which Weidmüller solutions are deployed.

This is a YouTube video. By clicking on this video, you agree to Google/YouTube's Privacy Policy & Terms of Use . You also agree to our Privacy Policy.

The rapidly-increasing use of sensors in the Smart Factory is giving rise to greater demand for high-performance infrastructure. This is essential for transferring signals and data quickly. The magic word here is Single Pair Ethernet – thanks to which, data can be transferred using a single pair of wires.

Weidmüller and partners from the field of electrical connectivity all rely on the innovative Single Pair Ethernet when developing new industry standards. This technology makes it possible to implement the Internet of Things consistently within industry, right through to field-based applications.

The network infrastructure for the Industrial IoT: Get to know the new Ethernet standard that combines reliable data transmission with long cable lengths, a compact design and robust cabling.

Do you have any questions about the Smart Factory or would you like us to advise you on the different options for how you can embark on the journey towards your own Smart Factory? Then fill out the form below, select your topic and our experts will contact you as soon as possible.