Industrial field wiring is a crucial aspect for the optimal functioning of production and automation systems in industry.

With the integration of industrial IoT and the associated data volumes, the complexity and demands on field wiring are growing. Modern industrial field wiring solutions are characterised by high modularity and plug-and-play capability. This enables fast installation and commissioning while reducing downtime during maintenance.

An end-to-end infrastructure creates significant added value in terms of efficiency, safety and flexibility of production processes. As an expert in industrial applications, Weidmüller offers a wide range of field wiring components. The portfolio is complemented by user-friendly services and individual consulting.

The customer needs an efficient and easy-to-install power supply for electric drives for horizontal conveyor technology.

Conventional methods such as supply from the control cabinet proved to be too complex and required a lot of space as well as material costs. Using a daisy chain between drives led to unwanted problems, including lack of space in the connection compartment and unnecessarily long cable ends. In this challenge, our customer was looking for a solution that was not only simple but also error-free.

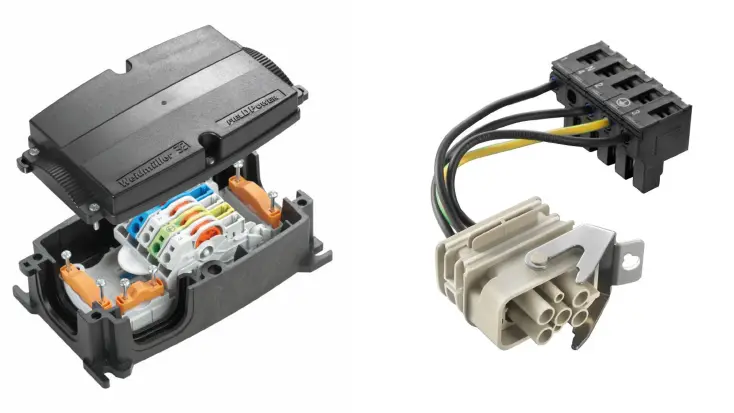

Thanks to FieldPower® contact modules, decentralised energy distribution can be implemented easily and error-free. With this decentralised solution, individual motors can be disconnected while the system continues to run. This leads to a significant reduction in downtime and maintenance costs.

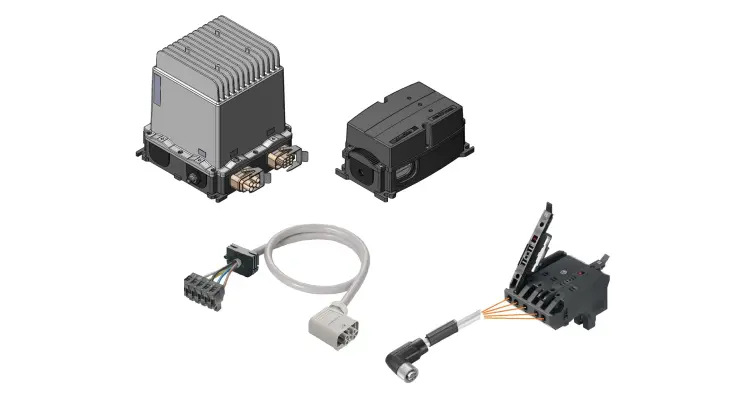

The empty enclosures, contact modules and connectors can be ordered separately. Thanks to this modular system, the ordering and assembly of the empty enclosures can take place during the mechanical process, while the contact modules only have to be clipped in later during the electrical assembly.

The pre-assembled cable sets and pluggable branch lines ensure simple and error-free installation.

For the construction of global logistics centres, conveyor lines must be supplied with 400VAC and 24VDC main and auxiliary power. The same applies to the control boxes required for each segment for the control and safety technology.

The installation should be carried out via modular systems with power supplies, power distributors and branch lines in IP65. Each individual conveyor segment must be put into operation immediately after the mechanical and electrical installation. Therefore, the necessary resources should be designed decentrally within the segments. Depending on customer requirements, the 24VDC power supply should be designed redundantly. The voltage drop should be kept as low as possible.

As a full-service provider, Weidmüller offers all components for a smooth 400V supply to the motors as well as 24VDC supply in the field. These include pluggable 3-phase power supplies as well as pluggable 400VAC and 24VDC distribution boxes. Thanks to IDC technology (insulation terminal), the energy cable can be used uncut – directly from the cable reel.

Weidmüller’s pre-assembled cables with plug-in connectors are used to connect the distribution box and motor – regardless of whether AC/DC and which connector face is required. The use of pre-assembled plug-in connectors or folding seals on the distribution boxes completes the overall package. This enables a simple, uncomplicated and error-free connection in the field.

In addition to simple logistics centres, cold storage facilities are also becoming increasingly important worldwide. The need for a solid infrastructure, short throughput times and high demands on occupational safety make partial or full automation unavoidable.

When building such systems, it is crucial to use solid technology that can withstand the cold temperatures and function flawlessly. The concept should be easy to integrate and scale at any global location.

For 400VAC power distribution within a fully automated cold store, FieldPower® was used to create a robust, error-free and easy-to-install concept. Thanks to the insulation displacement terminals of the distribution box (IDC), the taps can be mounted precisely to the motors, and additional work steps such as cutting, stripping and crimping are no longer necessary. With the plug already installed, installation to the motor is simply plug-and-play, which means that individual motors can also be switched off for maintenance purposes if necessary.

The overall solution with manufacturer-independent interfaces enables easy system integration with an operating temperature range of −40°C to +55°C. For the 400VAC power distribution, a simple connection of the power distribution box could be guaranteed. This makes commissioning easier in different markets.